5G Base Station Telecom Tower | Galvanized Lattice/Monopole, High Stability

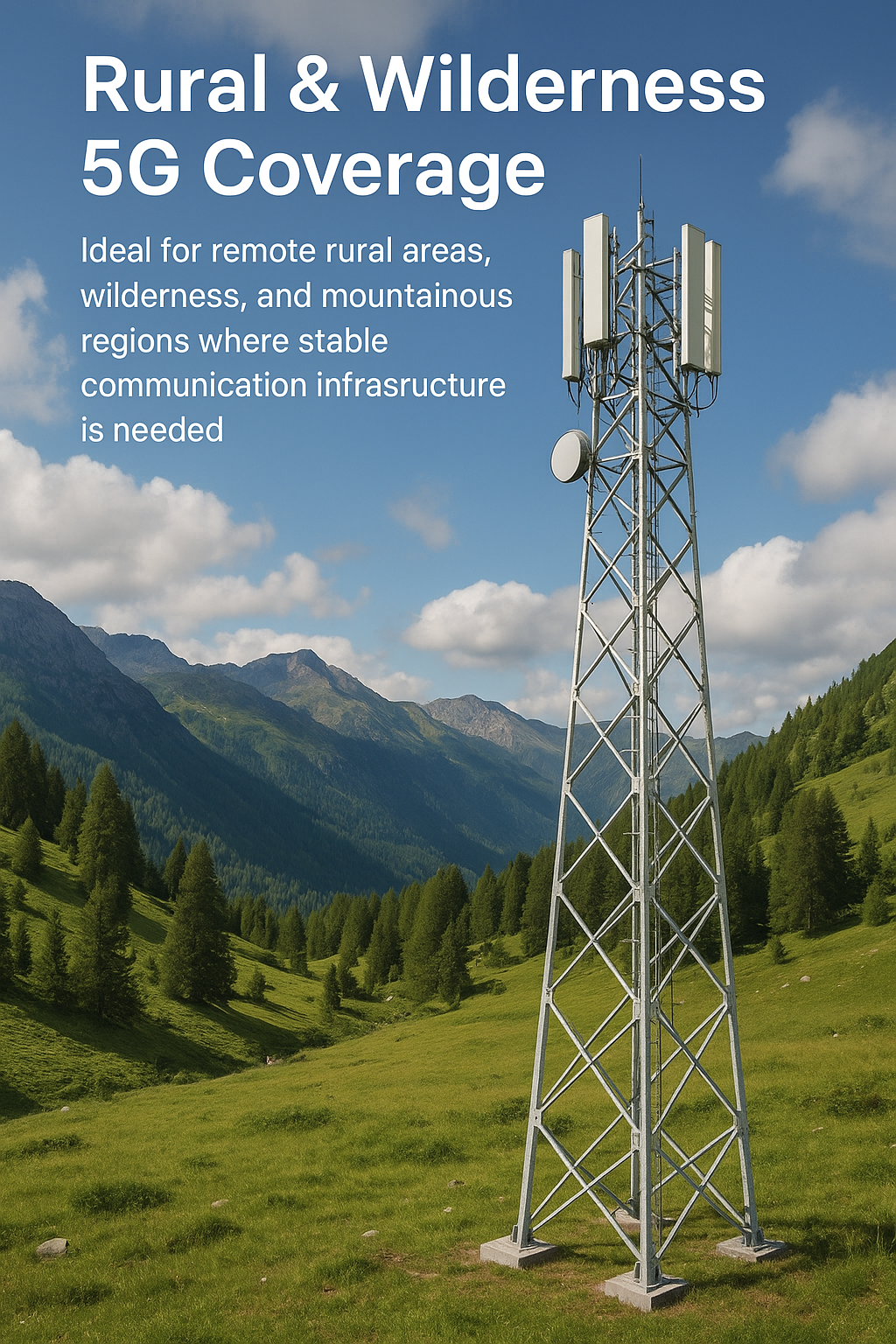

Welcome to explore our Telecom Tower solutions! angular, tubular,monopole,camouflage tower,guyed mast,steel pole, all with hot-dip galvanized anti-corrosion, 5G compatibility and quick deployment—perfect for rural, urban, scenic or emergency needs. Reliable, durable, and tailored for your communication projects!

Products Introduce

All Telecom Tower series crafted from Q235B/Q355 and Q420B high-strength steel with hot-dip galvanization (≥85μm) for 20-30 years of anti-corrosion performance. Designed for 3/4G/5G compatibility, making them ideal for rural coverage, urban landscapes, scenic areas, and emergency communication needs. Whether you require low-cost rural deployment, unobtrusive urban integration, or temporary emergency coverage, our Telecom Tower solutions deliver reliability, durability, and tailored adaptability for your communication projects.

Product Center

Product Advantages

Our Telecom Tower series stands out with advantages centered on two core dimensions—robust performance backed by premium craftsmanship, and flexible scenario adaptation that delivers tangible user value—each tailored to meet diverse communication project needs.

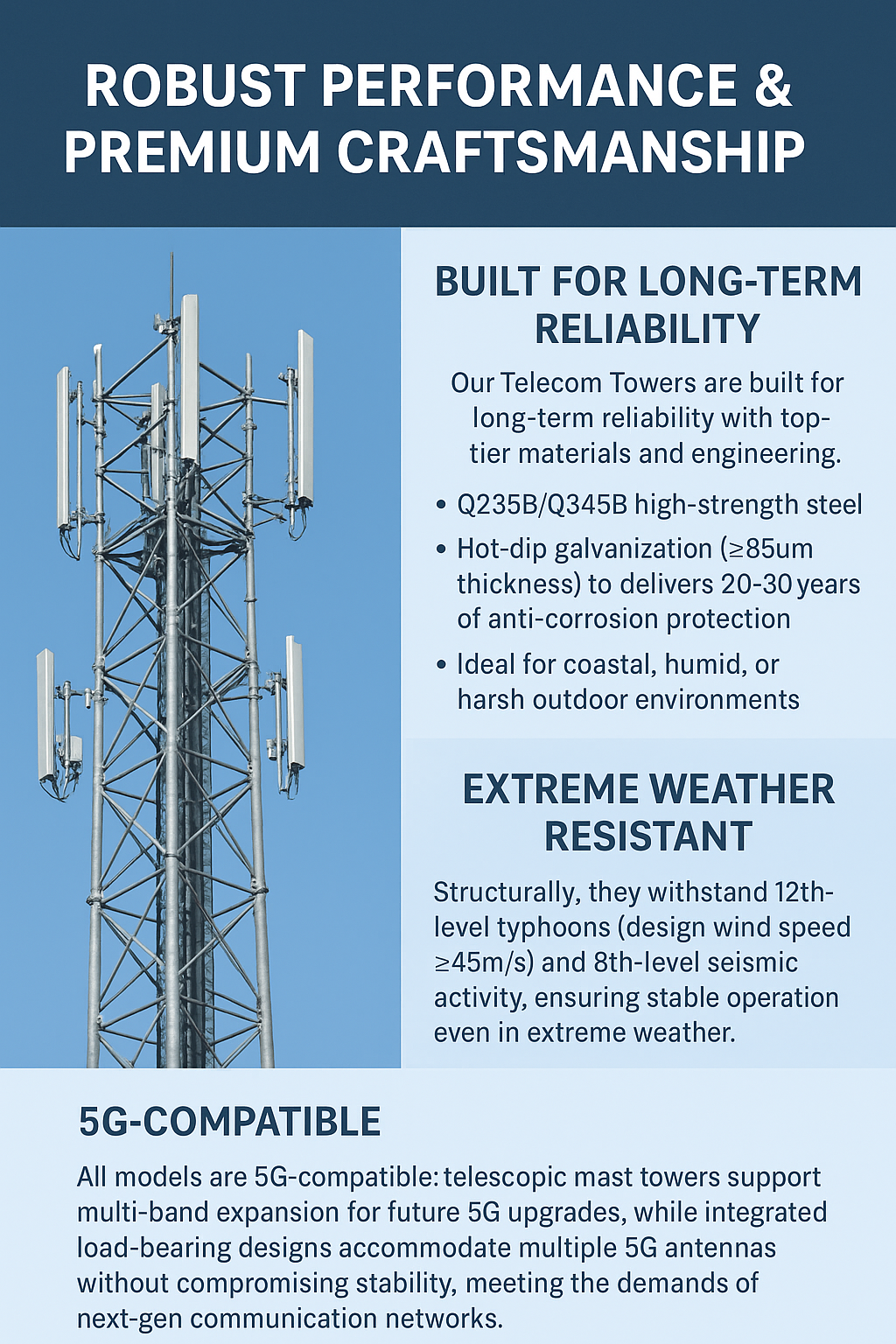

Robust Performance & Premium Craftsmanship

Our Telecom Towers are built for long-term reliability with top-tier materials and engineering. Crafted from Q235B/Q355 and Q420B high-strength steel, each tower features hot-dip galvanization (≥85μm thickness) that delivers 20-30 years of anti-corrosion protection—ideal for coastal, humid, or harsh outdoor environments. Structurally, they withstand 12th-level typhoons (design wind speed ≥45m/s) and 8th-level seismic activity, ensuring stable operation even in extreme weather.

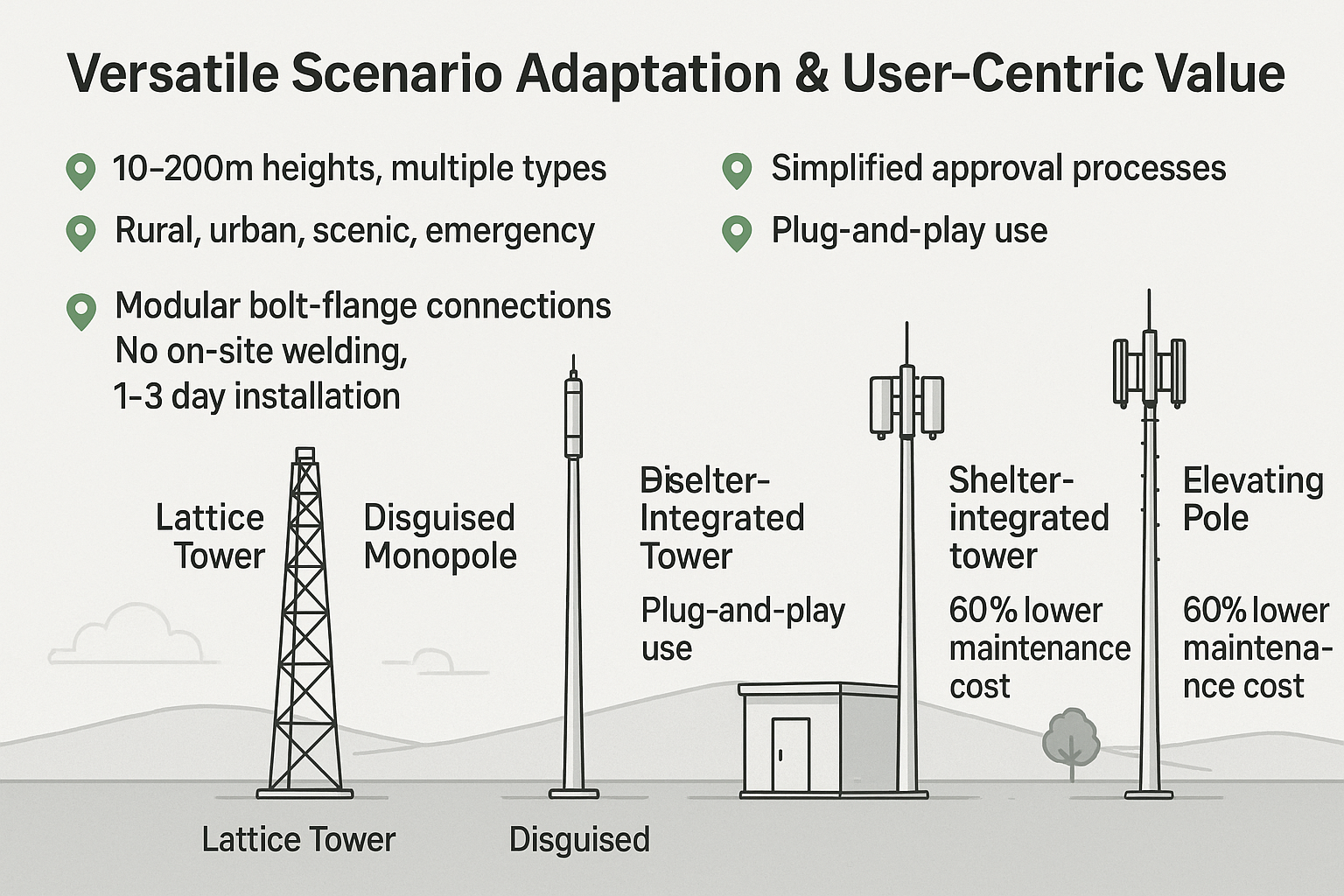

Versatile Scenario Adaptation & User-Centric Value

Designed to fit diverse application needs, the tower series covers 10-200m heights and multiple types (lattice, disguised monopole, shelter-integrated, elevating pole), adapting seamlessly to rural ,urban areas, scenic spots, and emergency sites.

Technical Specifications

Our Telecom Tower’s technical specifications lay a solid foundation for its reliable performance and multi-scenario adaptation, covering three key dimensions—structural & material basics, dimension & installation details, and functional adaptation & supporting systems—to provide clear, actionable parameters for your project selection.

Structural & Material Specifications

Core Material: Adopts Q235B/Q355 and Q420B high-strength structural steel, ensuring excellent load-bearing capacity (suitable for multi-antenna mounting of 5G base stations). Anti-Corrosion Process: Hot-dip galvanization in line with ISO1461/ASTM A123 standard—enabling 20-30 years of anti-rust performance (double-layer anti-corrosion optional for coastal high-humidity areas). Mechanical Performance: Designed to resist 12-level typhoons (maximum design wind speed ≥45m/s) and ≥8-level seismic intensity, meeting the stability requirements of harsh outdoor environments.

Functional Adaptation & Supporting Specifications

A telecom tower functionally adapts to support various antennas for wireless signal transmission, covering telephony, data, and broadcasting. Its supporting specifications include structural durability to withstand environmental loads, corrosion resistance, precise height for optimal coverage, and adequate weight capacity for antenna mounting. These features ensure reliable performance and longevity in diverse operational conditions.

Application

OEM Service

Comprehensive OEM Customization Scope

Cover end-to-end customization aligned with client requirements: Parameter Customization: Tailor tower type (angular/tubular/monopole/lattice), height (10-200m), and load-bearing capacity to match wind speed, seismic, and antenna-mounting demands. Scenario Adaptation: Adjust structures (corrosion-resistant coatings for coasts, wind-resistant designs for typhoon zones) and exteriors (camouflage for urban/scenic areas) per installation site conditions. Process & Material Tuning: Customize steel processing, surface treatments (hot-dip galvanization), and coatings to meet local industry standards.

Solid OEM Production Support

Ensure reliable, efficient OEM delivery with strong manufacturing capabilities: High Capacity: Monthly production of 6,000 tons, supported by 1,000+ skilled staff, to fulfill bulk or small-batch orders. Advanced Equipment: Use precision fabrication tools for cutting, welding, and galvanization to guarantee consistent quality. Strict QC: Conduct raw material checks, structural tests, and anti-corrosion assessments to meet global safety standards.

Core Advantages of Our OEM Service

Solve key telecom project pain points with tangible value: Precise Demand Matching: Involve clients in design/production to avoid product-site mismatches. Cost Optimization: Tailor designs to cut material/labor costs and reduce long-term maintenance expenses. Tech Compatibility: Design towers for 5G/IoT upgrades to extend lifecycle. Fast Deployment: Pre-engineer modular designs for ≤3-day on-site setup, accelerating network rollout.

Contact Us

If you have needs for telecom tower customization, OEM services, or project consultations, feel free to get in touch—we’ll respond promptly to support your communication infrastructure plans.

FAQs

Our Certificate

Our telecom tower solutions and OEM services are supported by authoritative certificates covering product quality, manufacturing compliance, and industry technical standards—effectively verifying our commitment to reliability and meeting global clients’ regulatory needs.

Related Blogs

-

With the support of modern factories and advanced equipment, we have successfully completed the custom production of a 30-meter,camouflaged palm tree telecom tower for our client in Côte d'Ivoire. This achievement highlights not only our strong production capabilities and stringent product qualitProjects

With the support of modern factories and advanced equipment, we have successfully completed the custom production of a 30-meter,camouflaged palm tree telecom tower for our client in Côte d'Ivoire. This achievement highlights not only our strong production capabilities and stringent product qualitProjects -

With the support of modern factories and advanced equipment, we have successfully completed the custom production of a 10m pole together with wire mesh fence for our client in Congo DRC. This achievement highlights not only our strong production capabilities and stringent product quality control,Projects

With the support of modern factories and advanced equipment, we have successfully completed the custom production of a 10m pole together with wire mesh fence for our client in Congo DRC. This achievement highlights not only our strong production capabilities and stringent product quality control,Projects -

We have successfully reached a cooperation agreement with Myanmar to supply low-voltage 33KV and 66KV power substation structure and support the development of the country's power infrastructure. The substation structures could enhance the stability and efficiency of Myanmar’s electricity transmisProjects

We have successfully reached a cooperation agreement with Myanmar to supply low-voltage 33KV and 66KV power substation structure and support the development of the country's power infrastructure. The substation structures could enhance the stability and efficiency of Myanmar’s electricity transmisProjects -

With the support of modern factories and advanced equipment, we have successfully completed the custom production of 40m and 50m angular telecom towers for our client in Ukraine. This achievement highlights not only our strong production capabilities and stringent product quality control, but also oProjects

With the support of modern factories and advanced equipment, we have successfully completed the custom production of 40m and 50m angular telecom towers for our client in Ukraine. This achievement highlights not only our strong production capabilities and stringent product quality control, but also oProjects

Keep In Touch With Us

Whether you have questions about telecom tower specs, need to discuss OEM customization, or want to consult on project cooperation—we’re ready to connect. Keep in touch with us, and let’s tailor solutions for your communication infrastructure needs.

Mob:+86-574-87143595

E-mail:tony@gte-cn.com